Lecture

Lecture

Bio-based aerogels: new eco-friendly porous materials for thermal insulation and controlled release

The Centre des Matériaux de l'École des Mines de Paris owns one multi-processes « CAPS » facilities (Controlled atmosphere Plasma Spraying).

The CAPS system consist in a 18 m3 chamber equipped with a robotized plasma spray unit (Sulzer-Metco). It is fitted for technology transfer and to achieve for coupons and demonstrating parts. With the controlled atmosphere: nature of filling gas (air, argon ou nitrogen), chamber pressure (2 to 350 kPa), temperature control (cooling and recirculating gas exchangers), this large scale facility can operate all the existing plasma spraying modes :

In addition to this various range of plasma spray processes for metals and ceramics, a cryogenic cooling can also be applied using the «ATC» system (CEA patented) with liquid pulsed argon (plasma forming of thick parts and spraying on heat sensitive polymers). Moreover, a semi-transferred arc (STA) system is also avalaible to combine an in situ treatment of the substrate (cleaning or heating) prior to plasma spraying.

The École des Mines de Paris has been equipped (with help of the Essonne's department Councyl, ASTRE fundings) with the more innovative spraying process to achieve the deposition of metals and cermet coatings applying the cold gas dynamic spraying or «cold-spray» technology.

This new facility, machined for industry and laboratory (CGT kinetic 3000 M, 30 kW, 30 bar, 600°C N2, 450°C He, Buse de Laval WC) improve the battery of spraying facilities avalaible at the Centre es Matériaux. The cold spray gun can be installed within the robotized CAPS chamber (then, the cold spray technology can be applied with vaccum and controlled atmosphere that make the equipment CAPS + COLD SPRAY unique in the world). When the cold spray system is not in the CAPS chamber, a conventional cold spray booth is also avalaible for the cold spraying of small coupons and the testing of powders.

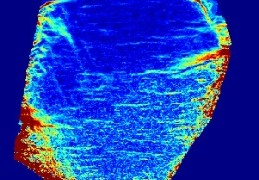

1 and 2 : numerical simulation of the crushing of a particle projected by cold spray (Ta on Cu),

thesis of Francesco Delloro, MINES ParisTech (2015)

3 - coating deposition : additive manufacturing by cold spray of a piece of Ti.

A new version of the COLD SPRAY CLUB website is now…

The COLD SPRAY CLUB concerns laboratories, technology…

> En savoir +

Formation

A MINES ParisTech PhD student awarded at the…

Josiane Nguejio, PhD student at Centre des Matériaux…

> En savoir +

Recherche

The FEMS Lecturers 2014-2015 include Henry PROUDHON

Lecturer Series This is a scheme which sponsors selected…

> En savoir +

Recherche

award for a team of Centre des Matériaux

Nicolas Gueninchault who work in teams M2 and COCAS with Henry…

> En savoir +

Recherche

The SF2M award three medals to doctors of the centre des…

The medal Réaumur is given by SF2M, each two…

> En savoir +