Lecture

Lecture

Bio-based aerogels: new eco-friendly porous materials for thermal insulation and controlled release

| Area of expertise | Materials science and engineering |

| Doctoral School | ISMME - Systems Engineering, Materials, Mechanics, Energy |

| Supervisor | Mme Anne-Françoise GOURGUES |

| Research unit | Centre of materials |

| Starting date | October 1st 2025 |

| Keywords | Fracture, Cleavage, Plastic deformation, Microtexture |

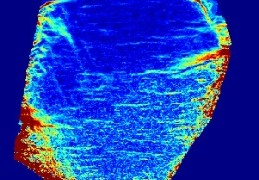

| Abstract | The prediction of failure modes in metallic structures is a key step in the safety assessment of industrial components subjected to significant mechanical loads (such as components in nuclear power plants, pipelines, etc.). In the nuclear sector, the structural integrity of components must be ensured throughout their entire service life, even in the event of an accident. There is increasing demand to demonstrate that components can withstand the risk of sudden fracture, and this requirement is now being extended to numerous piping systems and equipment. The underlying principle is to show that, even in the presence of a defect, the component can sustain the loads it may experience during operation. Special attention is given to brittle fracture by cleavage, due to its unstable and catastrophic nature that leads to immediate failure of the component. Brittle fracture is sensitive to the level of plasticity and triaxiality at the crack tip, which explains the beneficial structural effect often observed in real components compared to laboratory specimens. The industrial challenge lies in better understanding the role of plasticity, in relation to crystallographic microtexture, on brittle fracture, in order to improve current prediction criteria. The influence of plastic deformation on brittle fracture has been widely studied in the literature. Several mechanisms have been proposed to explain this effect, but it remains difficult to identify which ones are dominant, due to the coupling between various phenomena. For instance, the authors in [1] attribute the beneficial effect of plastic deformation on cleavage to the nucleation of cavities around carbides, which prevents the initiation of microcracks. Other authors [2] suggest that the evolution of cleavage stress with deformation results from morphological changes in the grains during loading, which alter the cleavage facets. This idea forms the basis of the plasticity correction in the well-known Beremin model [3]. More recently, researchers [4] studying the evolution of cleavage stress in a steel subjected to various predeformation levels have highlighted a corresponding evolution in crystallographic microtexture with plastic deformation. The concept of PCFs (Potential Cleavage Facets) was introduced groups of grains with nearly common {001} planes, oriented nearly perpendicular to the maximum principal stress. The size of these PCFs evolves with plastic deformation and correlates with cleavage stress, though this alone does not fully explain the observed variations. Moreover, predeformation also alters local plasticity and residual stresses, which may further impact cleavage fracture resistance. |

| Profile | Typical profile for a thesis at MINES ParisTech: Engineer and / or Master of Science - Good level of general and scientific culture. Good level of knowledge of French (B2 level in french is required) and English. (B2 level in english is required) Good analytical, synthesis, innovation and communication skills. Qualities of adaptability and creativity. Teaching skills. Motivation for research activity. Coherent professional project. Prerequisite (specific skills for this thesis): Metallurgy and mechanics (experimental background) Applicants should supply the following : a detailed resume a copy of the identity card or passport a covering letter explaining the applicants motivation for the position detailed exam results two references : the name and contact details of at least two people who could be contacted to provide an appreciation of the candidate Your notes of M1, M2 level of English equivalent TOEIC to be sent to recrutement_these@mat.mines-paristech.fr |

| Funding | Partenariat d'entreprises ou d'associations |

A new version of the COLD SPRAY CLUB website is now…

The COLD SPRAY CLUB concerns laboratories, technology…

> En savoir +

Formation

A MINES ParisTech PhD student awarded at the…

Josiane Nguejio, PhD student at Centre des Matériaux…

> En savoir +

Recherche

The FEMS Lecturers 2014-2015 include Henry PROUDHON

Lecturer Series This is a scheme which sponsors selected…

> En savoir +

Recherche

award for a team of Centre des Matériaux

Nicolas Gueninchault who work in teams M2 and COCAS with Henry…

> En savoir +

Recherche

The SF2M award three medals to doctors of the centre des…

The medal Réaumur is given by SF2M, each two…

> En savoir +