Lecture

Lecture

Bio-based aerogels: new eco-friendly porous materials for thermal insulation and controlled release

The pole "MIcrostructure, Mechanics and EXperimentation" (MIMEX) is positioned on all types of materials :

The pole "MIcrostructure, Mechanics and EXperimentation" (MIMEX) is positioned on all types of materials :

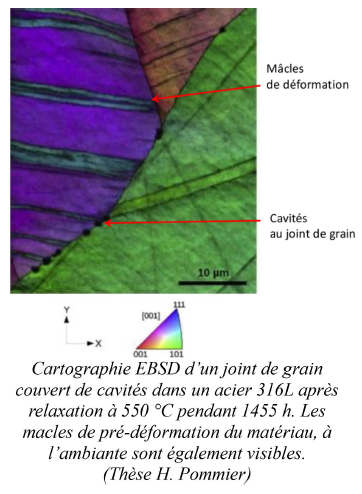

1) Metals and metal alloys,

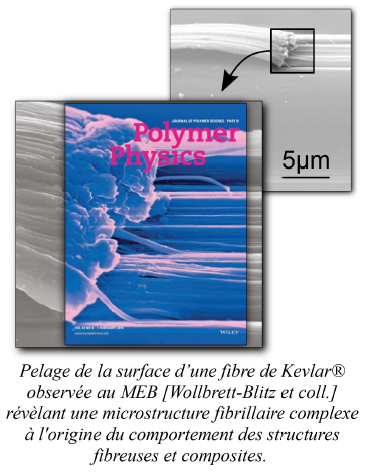

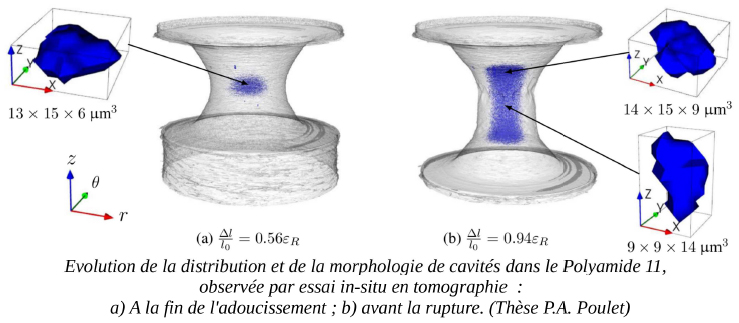

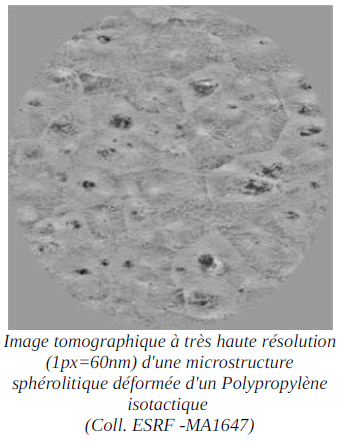

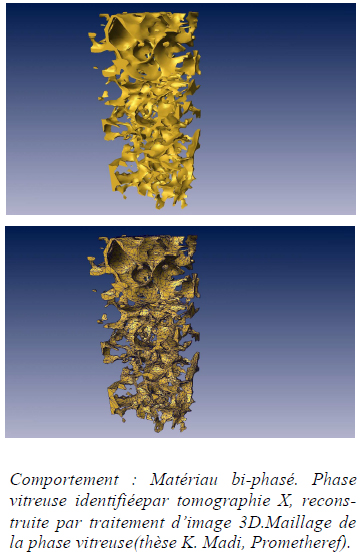

2) Polymers and composites with polymer matrices,

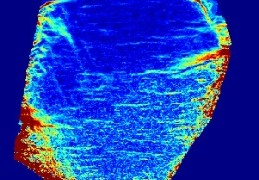

3) Ceramics and refractories.

The identification of the mechanisms of deformation, damage and rupture requires the collaboration of microstructural observation techniques, at different scales. For example, for composite materials, from the scale of a subsystem (a few tens of centimeters) to the scale of mono-filaments of a few micrometers in diameter. The relevance of the physical parameters to be taken into account, for each class of material, is based on a systematic study of the size of the experimental volume of interest as well as stochastic data in this volume. A permanent interaction is established between the experimentation and the modeling at the scale of the continuous medium since the conception of the tests until the structural computation, the aim being to target dedicated tests in agreement with the industrial and scientific problematic posed. The MIMEX cluster thus implements multi-scale experimentation and modeling linking the local approach (at the microstructure level) and the global approach (at the macroscopic scale). Integration into the (micro) structure calculation tools is done in cooperation with the Center's numericians (SIMS) and laboratories of other institutions.

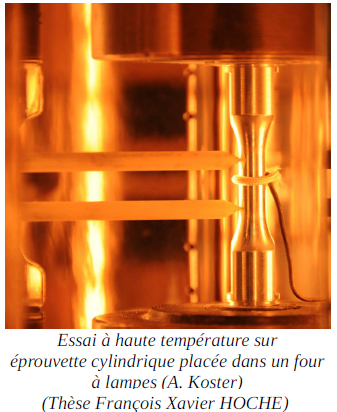

The analysis of the mechanisms of the physical phenomena involved requires the intensive use of microstructural observations at different scales and their quantitative description in order to introduce the relevant physical parameters into the proposed approach in experimental and theoretical mechanics. The microstructural evolution during a thermomechanical loading (during the implementation or during the service) is put forward. It allows :

1) the development of new materials,

2) the study of phase changes,

3) the analysis of aging phenomena during service (oxidation, damage, etc.)

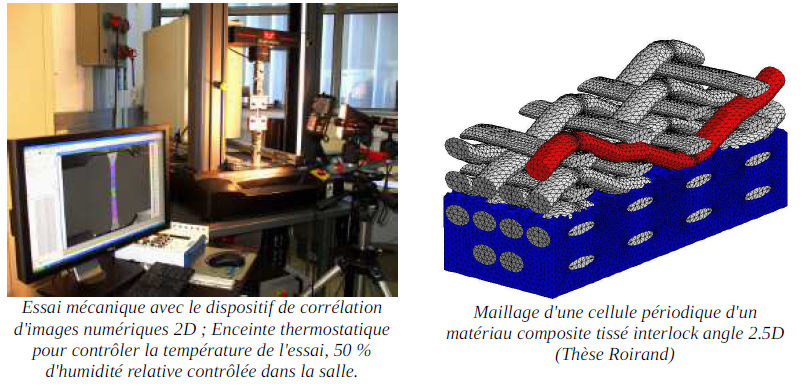

Focusing on the evolution of the microstructure during thermomechanical loading, the experiment develops on the constitution of database at the scale of the microstructure. The implementation of in situ tests in tomography / laminography has made it possible to access the mechanisms of volume deformation. Depending on the problem addressed, the MIMEX group offers and designs two types of mechanical tests.

Focusing on the evolution of the microstructure during thermomechanical loading, the experiment develops on the constitution of database at the scale of the microstructure. The implementation of in situ tests in tomography / laminography has made it possible to access the mechanisms of volume deformation. Depending on the problem addressed, the MIMEX group offers and designs two types of mechanical tests.

On the one hand, simple tests usable in an analytical way by optimizing the geometry of the test specimens and the instrumentation for an implementation at our industrial partners in order to improve an experimental methodology.

On the other hand, complex mechanical tests with advanced instrumentation and modeling, simulating a real load (aircraft engine cycle of a turbine blade) on an industrial structure. These tests can be done under a controlled environment (air, atmosphere, humidity, etc.) or even in a severe environment such as stress corrosion, in close collaboration with partners equipped for specific tests.

In interaction with the study of the evolution of the microstructure and the experimental mechanics, the pole implements the theories based on the mechanics of the continuous media, the homogenization, the mechanics of the damage and the mechanics of the rupture. The fine modeling of the physical phenomena is thus declined on two scales :

1) the global approach based on macroscopic observables dedicated to industrial parts in service,

2) the local approach supported by mechanisms at the microstructure level.

The latter brings the pole to perform microstructure calculations conducive to exchanges with materials developers. A strong interaction is made with the SIMS group to implement on the finite element code of the Center (Z-set) laws of behavior at various scales, coupled or not (post-treatment) with the damage.

The approach developed within the MIMEX group is based on the highlighting and observation of physical phenomena on the basis of which models are developed. These models are then validated on laboratory specimens, before being used to optimize the behavior of new materials for the processors and predict the life of industrial components for the operators. The expertise of physical mechanisms is aimed at all types of materials (metal alloys, polymers, polymer matrix composites, ceramics and refractories) and at all stages of the "life" of these materials.

The approach developed within the MIMEX group is based on the highlighting and observation of physical phenomena on the basis of which models are developed. These models are then validated on laboratory specimens, before being used to optimize the behavior of new materials for the processors and predict the life of industrial components for the operators. The expertise of physical mechanisms is aimed at all types of materials (metal alloys, polymers, polymer matrix composites, ceramics and refractories) and at all stages of the "life" of these materials.

The understanding of physical phenomena results from a strong coupling between, on the one hand, conventional mechanical characterization means (monotonic mechanical stress, fatigue, creep), in controlled environment (-196 °C to +2000 °C), or by the development of specific means (very low-load vacuum dilatometry, tensile-torsion machine, real-time determination of residual austenite, Gleeble), and secondly, the use of structural observation techniques (light and electron microscopy, EBSD, FIB, tomography / laminography). In order to better reproduce certain conditions encountered in service, a test platform up to 25 m/s with temperature setting (- 130 °C to + 300 °C) allows the study of the behavior and the rupture under fast solicitations.

______________________________________________

A new version of the COLD SPRAY CLUB website is now…

The COLD SPRAY CLUB concerns laboratories, technology…

> En savoir +

Formation

A MINES ParisTech PhD student awarded at the…

Josiane Nguejio, PhD student at Centre des Matériaux…

> En savoir +

Recherche

The FEMS Lecturers 2014-2015 include Henry PROUDHON

Lecturer Series This is a scheme which sponsors selected…

> En savoir +

Recherche

award for a team of Centre des Matériaux

Nicolas Gueninchault who work in teams M2 and COCAS with Henry…

> En savoir +

Recherche

The SF2M award three medals to doctors of the centre des…

The medal Réaumur is given by SF2M, each two…

> En savoir +