Lecture

Lecture

Bio-based aerogels: new eco-friendly porous materials for thermal insulation and controlled release

The "Surfaces, Interfaces, Procédés" group seeks to develop new functional materials by establishing the relationships between the process parameters, the structures at different scales (from nano to macro) and the physical properties of the shaped materials, including their mechanical properties. This approach, which is largely supported by the extensive means of characterizing the microstructures available at the center, combines the skills and know-how of experimenters and modellers, and allows industrial processes to be revisited by bringing new lighting and a more in-depth understanding of the phenomena at play, as well as designing completely new processes, materials and even parts using our multi-material and / or multi-scale vision. The activities are therefore primarily focused on industrial partnerships, until the transfer of technology.

"TRADITIONAL" PROCESSES (powder metallurgy)

Person in charge : Yves BIENVENU

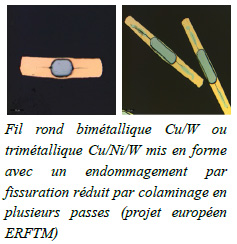

"Traditional" production processes use either the liquid phase (molding ...) of ready-to-use materials after surface finishing operations or thermomechanical treatments, or solid phase diffusion. Related processes can be grouped under the term Powder Metallurgy, which also includes ceramic materials. The reasoning in the solidification studies is based on thermodynamics, and can be guided by simple equilibrium calculations (Calphad, Thermocalc) and by the results of chemical and thermal analyzes, taking into account interfacial phenomena and the kinetics (flows and diffusion accompanying the change of liquid-solid state).

OUT OF EQUILIBRIUM PROCESSES

People in charge : Francesco DELLORO, Michel JEANDIN

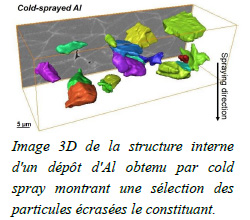

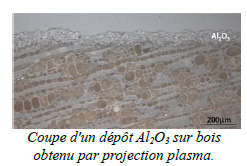

These processes encompass in the pole the plasma projection and the cold spray projection. The supply of energy (thermal or kinetic) in a very short time leads to non-equilibrium interfaces or structures. Very different (and even not very compatible) materials can combine to form many substrate-coating couples, including metallization or ceramization of polymers or fabrics, increasing the possibilities of new functional materials. The understanding and improvement of these processes are based on specific characterizations (LASAT : laser shock for adhesion testing) and modeling, for example by finite elements for the particle-substrate collision in cold-spray.

These processes encompass in the pole the plasma projection and the cold spray projection. The supply of energy (thermal or kinetic) in a very short time leads to non-equilibrium interfaces or structures. Very different (and even not very compatible) materials can combine to form many substrate-coating couples, including metallization or ceramization of polymers or fabrics, increasing the possibilities of new functional materials. The understanding and improvement of these processes are based on specific characterizations (LASAT : laser shock for adhesion testing) and modeling, for example by finite elements for the particle-substrate collision in cold-spray.

ASSEMBLY METHODS

People in charge : Sébastien JOANNÈS, Jacques RENARD

This research area covers multi-material mechanical assemblies such as riveting, gluing or welding composite structures with polymeric or metallic sub-assemblies. The notion of assembly extends to multi-functional assemblies by responding to changing markets. Indeed, to meet the economic challenges, composite materials are increasingly brought to integrate functionalities that go beyond mechanical properties : the composites of tomorrow will be "intelligent and hybrid" multiplying interfaces and assemblies. The desired functionalities are multiple : it can for example be to capture information (detection of defects) or react to a specific environment. Composite materials must for that purpose integrate sensitive elements (electronic elements in particular) and this hybridization / functionalization must take place on the scale of the constituents themselves. Functions can now be provided on the fibers themselves by incorporating fillers and additives before extrusion and spinning. It is important to understand the complexity of new interfaces created so as not to deteriorate the primary functionalities such as mechanical strength and especially durability.

WET PROCESSES

People in charge : Anthony CHESNAUD, Jean-François HOCHEPIED, Alain THOREL

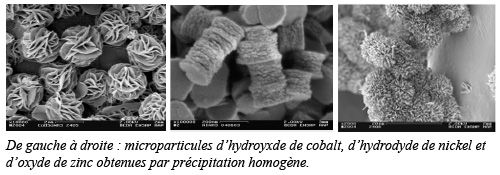

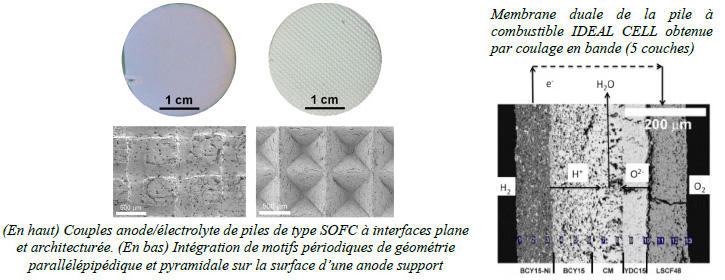

These methods make reference both to particle synthesis by precipitation and to powder shaping for the production of ceramics, for example tape casting for fuel cells. The controlled precipitation in aqueous solutions in suitable reactors, mainly applied to metal oxides, makes it possible to obtain a good compromise between control of the physico-chemical characteristics of the particles (purity, size, shape, etc.) and an industrially acceptable process, which distinguishes our work from soft chemistry academic approaches allowing often better particle control but appearing unrealistic on an industrial scale (especially in terms of cost), and pure process engineering approaches that only take into account rough characterization and control of particle size or morphology.

These methods make reference both to particle synthesis by precipitation and to powder shaping for the production of ceramics, for example tape casting for fuel cells. The controlled precipitation in aqueous solutions in suitable reactors, mainly applied to metal oxides, makes it possible to obtain a good compromise between control of the physico-chemical characteristics of the particles (purity, size, shape, etc.) and an industrially acceptable process, which distinguishes our work from soft chemistry academic approaches allowing often better particle control but appearing unrealistic on an industrial scale (especially in terms of cost), and pure process engineering approaches that only take into account rough characterization and control of particle size or morphology.

The tape casting, screen printing or film coating, developed in the laboratory, are "wet processes" involving a cold forming with a slurry followed by frying and sintering. The most delicate point is the stabilization of the slurry (against flocculation and sedimentation), asking to readjust their formulation according to the characteristics of the powders (grain size, surface charge, morphology and crystallochemical nature). Dominating the formulation of the slurries makes it possible, for example, to control and therefore optimize the porous microstructures of fuel cells, combining different materials.

______________________________________________

Constance Chanh, Ana�s Gourment, Betrand Petit, Anne-Fran�oise Gourgues-Lorenzon. Experimental determination of 3D crack propagation scenario in resistance spot welds of a martensitic stainless steel International Journal of Fracture, Springer Verlag, In press, ⟨10.1007/s10704-022-00626-2⟩

Raffaele Russo, Vikram Phalke, Didier Croizet, Mustapha Ziane, Samuel Forest, Frank Andr�s Girot Mata, Hyung-Jun Chang, Arjen Roos. Regularization of shear banding and prediction of size effects in manufacturing operations: A micromorphic plasticity explicit scheme International Journal of Material Forming, Springer Verlag, 2022, 15 (3), pp.21. ⟨10.1007/s12289-022-01657-9⟩

Kevin Pachuta, Halyna Volkova, Benjamin Hirt, Marie-H�l�ne Berger, Emily Pentzer, Alp Sehirlioglu. Liquid?phase exfoliation method to access cobalt oxide nanosheets in pH?neutral solutions Journal of the American Ceramic Society, Wiley, 2022, 105 (3), pp.1904-1912. ⟨10.1111/jace.18199⟩

Vikram Phalke, Tobias Kaiser, Jean?michel Scherer, Samuel Forest. Modeling size effects in microwire torsion: A comparison between a Lagrange multiplier-based and a CurlF p gradient crystal plasticity model European Journal of Mechanics - A/Solids, Elsevier, 2022, pp.104550. ⟨10.1016/j.euromechsol.2022.104550⟩

Tatu Pinomaa, Matti Lindroos, Paul Jreidini, Matias Haapalehto, Kais Ammar, Lei Wang, Samuel Forest, Nikolas Provatas, Anssi Laukkanen. Multiscale analysis of crystalline defect formation in rapid solidification of pure aluminium and aluminium?copper alloys Philosophical Transactions of the Royal Society A: Mathematical, Physical and Engineering Sciences, Royal Society, The, 2022, 380 (2217), ⟨10.1098/rsta.2020.0319⟩

Flavien Ghiglione, Samuel Forest. On the torsion of isotropic elastoplastic Cosserat circular cylinders Journal of Micromechanics and Molecular Physics, World Scientific Publishing, 2022, pp.1-14. ⟨10.1142/S2424913021420078⟩

St�phane Gillet, Thomas Jacopin, S�bastien Joann�s, Nacera Bedrici, Lucien Laiarinandrasana. Short-term creep and low cycle fatigue unified criterion for a hybridised composite material International Journal of Fatigue, Elsevier, 2022, 155, pp.106571. ⟨10.1016/j.ijfatigue.2021.106571⟩

Matti Lindroos, Jean-Michel Scherer, Samuel Forest, Anssi Laukkanen, Tom Andersson, Joona Vaara, Antti M�ntyl�, Tero Frondelius. Micromorphic crystal plasticity approach to damage regularization and size effects in martensitic steels International Journal of Plasticity, Elsevier, 2022, 151, pp.103187. ⟨10.1016/j.ijplas.2021.103187⟩

Vincent Maurel, Marion Bartsch, Marie-Helene Vidal-S�tif, Robert Va�en, Vincent Guipont. Coated single crystal superalloys: processing, characterization, and modeling of protective coatings Nickel Base Single Crystals Across Length Scales, Elsevier, pp.283-338, 2022, ⟨10.1016/B978-0-12-819357-0.00018-4⟩

A new version of the COLD SPRAY CLUB website is now…

The COLD SPRAY CLUB concerns laboratories, technology…

> En savoir +

Formation

A MINES ParisTech PhD student awarded at the…

Josiane Nguejio, PhD student at Centre des Matériaux…

> En savoir +

Recherche

The FEMS Lecturers 2014-2015 include Henry PROUDHON

Lecturer Series This is a scheme which sponsors selected…

> En savoir +

Recherche

award for a team of Centre des Matériaux

Nicolas Gueninchault who work in teams M2 and COCAS with Henry…

> En savoir +

Recherche

The SF2M award three medals to doctors of the centre des…

The medal Réaumur is given by SF2M, each two…

> En savoir +