Lecture

Lecture

Bio-based aerogels: new eco-friendly porous materials for thermal insulation and controlled release

The proliferation in recent years of articles and patents, regional and national initiatives around the direct additive manufacturing of structural steel parts testifies to the interest in this new method of manufacture by academic and industrial actors, as well as by the public authorities. This class of processes is indeed at the heart of the programs of the 4.0 plant. The Centtre des Matériaux, thanks to its multiple expertise in the physics of matter transformation in non-equilibrium conditions, in the development and simulation of innovative processes, in the design of microstructures as well as in the characterization and simulation of thermomechanical behavior and life expectancy, is a major player in this theme. He has been active since the early 2000s in several consortiums including academics, end-users of aeronautics or bio-medical, molders or toolmakers.

The creation of the FAMHES transverse axis mobilizing all of the laboratory's clusters provides an adapted response to the highly interdisciplinary character of the research theme around additive manufacturing. It aims to increase our visibility in strategic alliances with the industrial and academic worlds, to create a single and structured window in our exchanges with our partners and to support the investments considered priority by MINES-ParisTech. This axis deals with the process of selective laser melting of powder beds as well as the laser projection process which allows the addition of functions on existing parts or the repair of used parts. It brings together the multiple expertise of the three areas :

Beyond the Materials Center, a close collaboration has been established with the Centre de Mise en Forme (CEMEF) of MINES ParisTech in Sophia Antipolis for the numerical simulation of the shapes and dimensions of molten baths and microstructures generated.

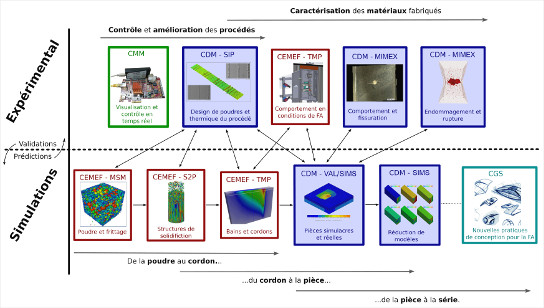

Mapping of the "Additive Manufacturing" activity at MINES ParisTech led by the Centre es Matériaux.

The transverse axis FAMHES federates skills in elaboration / characterization / simulation

of the three SIP / MIMEX / SIMS poles of the CDM.

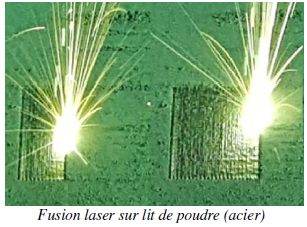

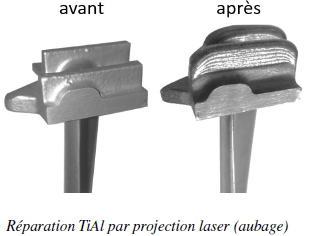

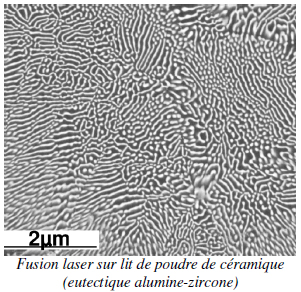

This transverse axis FAMHES on the additive manufacturing of shaped parts deals with the selective laser melting of powder beds as well as the laser projection. By these processes, the combination of new possibilities in terms of geometries and materials opens the door to the design of innovative components to increase operating temperatures, lighten structures (architectural materials) and increase the demands mechanical compared to traditional casting processes. The laser projection also allows the addition of functions on existing parts or the repair and anti-wear coating (hardfacing) of used parts. The development of additive processes is based on a multidisciplinary approach based on the human skills and technical resources of the three groups of the Centre dess Matériaux in the fields of elaboration, metallurgy, mechanics and numerical simulation of materials and materials. processes.

This transverse axis FAMHES on the additive manufacturing of shaped parts deals with the selective laser melting of powder beds as well as the laser projection. By these processes, the combination of new possibilities in terms of geometries and materials opens the door to the design of innovative components to increase operating temperatures, lighten structures (architectural materials) and increase the demands mechanical compared to traditional casting processes. The laser projection also allows the addition of functions on existing parts or the repair and anti-wear coating (hardfacing) of used parts. The development of additive processes is based on a multidisciplinary approach based on the human skills and technical resources of the three groups of the Centre dess Matériaux in the fields of elaboration, metallurgy, mechanics and numerical simulation of materials and materials. processes.

Beyond the determination and optimization of healthy part manufacturing parameters, the scientific objective is to better understand the physical mechanisms leading to :

i) the melting of a granular medium by the interaction of laser radiation and the stability of the liquid bath,

ii) the solidification and development of microstructures under severe conditions of thermal gradients and solidification rates, and

iii) the genesis of defects and residual stresses in manufactured parts.

This understanding contributes to improving the reliability of components with the development of process control, powder recycling and post-process control. This approach paves the way for the shaping of innovative materials that are sensitive to cracking. This includes a "design" of powders that must be adapted to the additive manufacturing according to the specifications of the intended application.

This understanding contributes to improving the reliability of components with the development of process control, powder recycling and post-process control. This approach paves the way for the shaping of innovative materials that are sensitive to cracking. This includes a "design" of powders that must be adapted to the additive manufacturing according to the specifications of the intended application.

The additive manufacturing of parts raises the question of their lifetime under realistic operating conditions. The prediction of the service life depends on the knowledge of the mechanisms of deformation, damage and rupture according to the typology and the size of the defects still existing after manufacture.

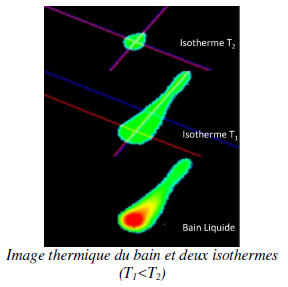

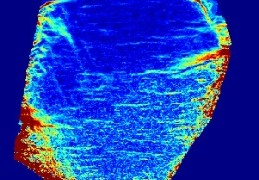

Process control during laser powder bed melting is based on the measurement of local thermal fields in real time of the liquid bath associated with its dimensions, surface area and morphology. The instantaneous temperature mapping makes it possible to calculate the local thermal gradients (measured at 4 points of the liquid bath) for :

The final objective is to propose a tomography of defects of the part during manufacture and recognizable by their thermal signature.

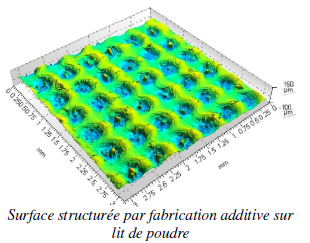

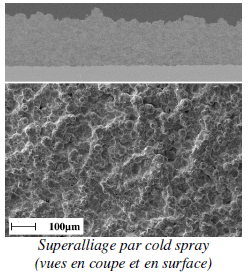

The significant growth of additive manufacturing strengthens that of powder spraying processes for coating or repairing surfaces, but also for forming mono- or multi-material preforms. The projection of powders makes it possible to repair or add new functions to the part resulting from additive manufacturing whose surface state must be mastered by completion or even structured. This concerns primarily fusion processes such as plasma projection, laser projection (cladding) or solid state as the dynamic projection by cold gas called "cold spray". All of these methods are based on controlling the states of matter at the powder particle scale throughout the incremental process and in relation to the out of equilibrium transformations experienced by the material. The reconciliation of these different "powder" processes within the FAMHES axis makes it possible to implement them and combine their advantages, from the manufacturing to the functionalization of the parts.

The significant growth of additive manufacturing strengthens that of powder spraying processes for coating or repairing surfaces, but also for forming mono- or multi-material preforms. The projection of powders makes it possible to repair or add new functions to the part resulting from additive manufacturing whose surface state must be mastered by completion or even structured. This concerns primarily fusion processes such as plasma projection, laser projection (cladding) or solid state as the dynamic projection by cold gas called "cold spray". All of these methods are based on controlling the states of matter at the powder particle scale throughout the incremental process and in relation to the out of equilibrium transformations experienced by the material. The reconciliation of these different "powder" processes within the FAMHES axis makes it possible to implement them and combine their advantages, from the manufacturing to the functionalization of the parts.

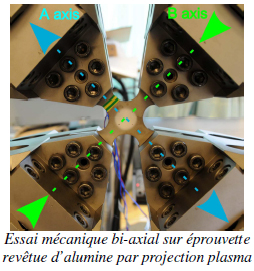

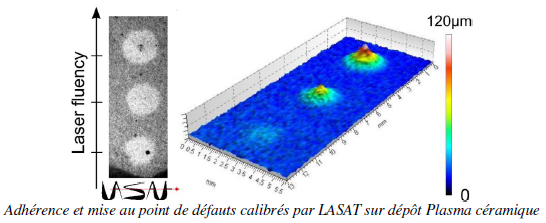

When the life of the parts is conditioned by that of a coating in a severe environment (corrosion, wear, thermal and mechanical shocks, etc.) then the mechanical strength of the interfaces and the resistance of the coating to the damage are crucial. The shock wave propagation LASAT mechanical test is developed for the non-destructive measurement of the adhesion of coatings. The analysis at different scales (nano-micro-macro) and the modeling of the thermomechanical behavior and the damage of the coated systems lead to the prediction of the service life.

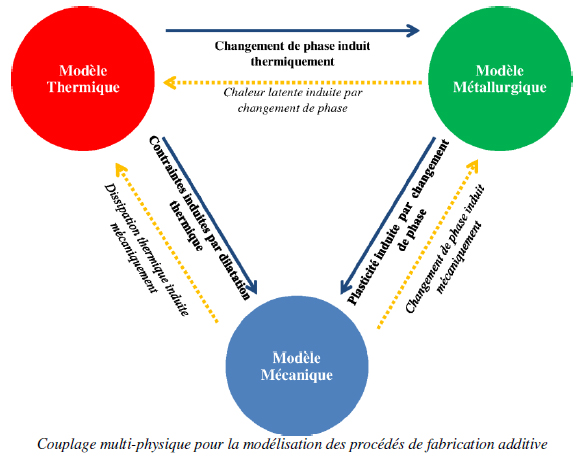

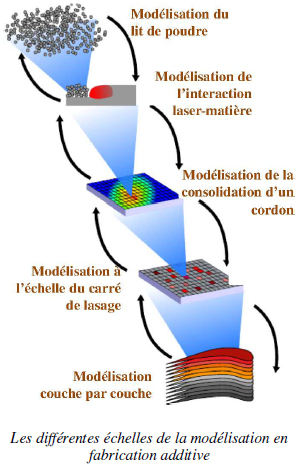

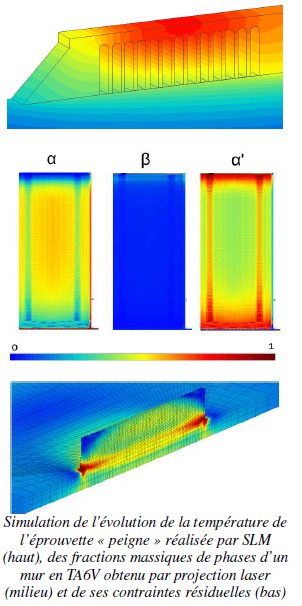

The design and dimensioning of complex parts is now based on numerical simulation, which makes it possible to reproduce the solicitations resulting from their development and their operating conditions. In the case of a part obtained by additive manufacturing, it is important to simulate as faithfully as possible the process and its associated phenomena from the manufacturing stage. Simulation allows thermal, metallurgical and mechanical effects during manufacture to be considered as a robust tool for i) estimating residual stresses and associated deformations and ii) predicting the microstructure resulting from the fabrication and its evolution during post-treatment stress relieving, recrystallization or precipitation.

The simulation of these processes is then dominated by the multiphysical and multiscale aspects (from the liquid bath to the room). Due to the excessive duration of current simulations (even longer than manufacturing), no software has yet been adopted for additive manufacturing. The FAMHES axis of the Centre des Matériaux and the Centre de Mise en Forme des Matériaux (based near Nice) combine their efforts and invest in their own works combining simulation and validation experiments for the development of a business code applicable to the field of additive manufacturing both on powder bed and by laser projection. The objective of such a software is to simulate the manufacture of shaped and industrial size parts in reasonable computing times, while taking into account the boundary conditions closest to reality; its purpose being an aid to the production of parts ready for use.

A new version of the COLD SPRAY CLUB website is now…

The COLD SPRAY CLUB concerns laboratories, technology…

> En savoir +

Formation

A MINES ParisTech PhD student awarded at the…

Josiane Nguejio, PhD student at Centre des Matériaux…

> En savoir +

Recherche

The FEMS Lecturers 2014-2015 include Henry PROUDHON

Lecturer Series This is a scheme which sponsors selected…

> En savoir +

Recherche

award for a team of Centre des Matériaux

Nicolas Gueninchault who work in teams M2 and COCAS with Henry…

> En savoir +

Recherche

The SF2M award three medals to doctors of the centre des…

The medal Réaumur is given by SF2M, each two…

> En savoir +